Analysis of 2012 small and medium enterprises will be taken electroplating marketing strategy

リリース日:2013-07-29 00:00 ソース:http://www.patchina.com.cn クリック:

With the world economy and China and other countries deteriorating macroeconomic environment in China, Guangdong and other places most of the small and medium enterprises are facing this metal plating tremendous pressure to survive. Small and medium enterprises do not just accept electroplating increasingly intense competitive pressures within the industry, but also to change the face of domestic macroeconomic environment and European environmental laws adjusted to blackmail. In this unfavorable environment, as the foundation of industrial manufacturing, metal plating industry (especially small and medium metal plating companies) how to survive and carry out? This paper LH electroplating factory in Shenzhen City, for example, detailed exposition of the Shenzhen SME metal plating enterprises in the new situation of the marketing strategy.

First, the whole of Guangdong market area metal plating industry is facing crises

(01) lead to the country's macroeconomic environment, rising costs.

2008 lot of variables in the macroeconomic environment. Much appreciated, deflation, and the introduction of the new labor law, and many other elements of the global economic crisis, making China's manufacturing industry in more than a decade experience flourished after experiencing the most severe challenge.

1, by the yuan's appreciation against the dollar impact of money constantly getting worse.

Electroplating enterprises in the high-end metal processing enterprises as key customers. Qi Cheng metal processing enterprises in export business mainly affected by exchange rate seriously. Money exchange rate changes on export prices influence. The money dollar exchange rate of 1:8.3 to 1:6.8 this year, the money for the dollar exchange rate rose by about 20%. The export business is far lower than the price rose 20%. Metal processing enterprises must be transferred to these pressures local electroplating enterprises body. Electroplating enterprises originally not make a big profit margins further tightening.

2, China People's Bank of deflation strategy adopted, the market is in the doldrums of the fuse.

Deflation brings more significant impact is progressive labor costs. With the price level rises, the overall level of resident life and death landing, to bring upward pressure on labor costs. The pressure of rising costs on to customers is difficult to complete the transfer.

3, the relevant state departments issued a new labor law, for the business sector had a negative impact.

The new labor contract law purposes, although safeguarding the interests of workers, but also brought the rise of labor costs. After the implementation of the new labor law, corporate salaries, benefits and related costs increased significantly.

4, the economic crisis

In early 2007, by the U.S. subprime mortgage crisis triggered by the global financial crisis, leading to a global recession. Electroplating industry is more seriously affected industries.

First, the global economic crisis has lead to consumer demand for landing. Second, the economic crisis countries will enhance the maintenance of domestic enterprises, and progress on the Chinese hardware products import barriers, thus affecting the metal plating business growth.

The four elements of metal plating companies directly incurred increased costs, which will certainly cause a lower cost developed countries to Vietnam and other Southeast Asian countries or regions metastasis. And this on the metal plating companies, the shrinking market will intensify competition within the industry.

(02) European and American consumer safety laws regulate access progress

In 2008, the United States issued a recall for Mattel co-handsome thing "Consumer Product Improvement Act of peace", the EU RoHS Directive subsequent progress on eight heavy metal testing specifications.

"Consumer safety improvement act" within the product is mainly aimed at children of lead and phthalates made to understand the request; EU RoHS specifications mainly for electrical and electronic equipment for lead, mercury, chromium and other heavy metals presents eight kinds understand the request.

The introduction of these compulsive decrees progress China export product testing specifications. This process for electroplating industry and raw materials put forward higher request, business operation costs significantly increased. Due to these norms to pay higher costs, making the loss of low-cost Chinese manufacturing competitive advantage. Metal plating industry was seriously affected, so always ignore environmental maintenance of metal plating industry fall into crisis.

(03) the increasingly fierce competition in the industry

The low-end market with the necessary plating low barriers to entry. 100,000 yuan will be able to engage in a small electroplating factory in Shenzhen, which makes the recent emergence of a large number of low-end metal plating factory. Coupled with the low-end market, market homogeneity, product homogeneity is very serious, leading to the fierce competition in the low-end market. Especially in recent years, clearly felt that the price getting lower and lower, increasing customer requests.

The high-end market because the scope of the required funding, technical strength, and high barriers to entry, business practitioners is much less than the low-end market. Related to the dispersion of the low-end market, high-end market concentration is high, competition is relatively mild and more. However, progress in Europe and consumer safety laws regulate access to high-end market has accelerated in the market homogeneity, product homogeneity aspects of trends, competition gradually intensified.

From the above analysis shows that market homogeneity and product homogeneity throughout the electroplating industry will intensify competition, whether it is in the low-end or high-end electroplating enterprises will gradually lose my competitive edge.

Second, the metal plating industry is facing critical issues

From the above analysis we can see, metal plating companies are now faced with two key problems: First, to digest in the macroeconomic environment and consumer safety laws in Europe and America under the influence of these two elements of the capital increase; Second, how in the increasingly fierce competition in the industry to survive and carried out. Rising costs and the homogenization of the whole electroplating industry will accelerate the deterioration of the industrial environment, whether it is at the low end or high-end electroplating enterprises will gradually lose my competitive edge.

That's before us is a problem in practice, electroplating enterprises to regain my competitive advantage.

Competitive advantage is a relative concept, the key is for the customer who can invent more than the value of its paid capital. About electroplating enterprises, this value is derived from the first low-cost, two is derived from the market and the product homogeneity break, looking for my blue ocean. Here is an example of Shenzhen LH plating, meticulous elucidated.

Third, the metal plating industry, low-cost strategy

From a global perspective, China is at the lowest level of metal processing industry, multi-industry enterprise engaged in low value-added metal processing, earned a meager processing fees. Practice under the present conditions of metal plating enterprises to reduce costs with very limited space.

In addition to reducing raw material procurement costs, improve labor efficiency, reduce inventory costs, layoffs and pay cuts, moving to lower-cost regions, such as conventional methods, it should also stop innovation in marketing, seeking ways to reduce costs.

(001) through technical innovation and development of less expensive alternative raw materials

First, think LH plating materials from alternative development to proceed reduce costs. Color products, for example nickel metal plating analyze the composition of capital. Shown in Fig.

Table I: nickel plating products constitute capital

Composition of nickel sulfate, nickel brightener other auxiliary board

The proportion of total capital 50% 30% 10% 10%

Table 1 shows the proportion of nickel plate to reach 50% of total cost, if the request is processed products of nickel-plated, then nickel plate is not being replaced. However, nickel sulfate, brightener and accessories is indeed able to replace.

One, LH plating nickel sulfate attempt to stop the main raw material substitution. Through experiments and found that magnesium sulfate Nickel sulfate has a good alternative, but does not affect the plating quality. This is an annual 75 percent for the company thrifty nickel sulfate capital.

Second, the development of nickel sulfate in victory replacement products, but also try to independent research brightener. Brightener price is high, accounting for 10% of total cost of plating, previously mainly by outsourcing. After nearly three months of development, LH electroplating brightener formulations developed. I began using brightener consumption. This backward integration parsimonious 50% per year for the company brightener capital.

Based on the above two nickel-colored unit cost reduction of 27.5%.

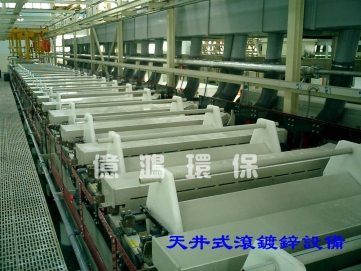

(002) Product Line modernization

Currently, the entire metal plating industry are using the traditional manual operation. Not only inefficient, but also by the operating personnel plating influenced the quality of instability. Scrap bad rate as high as 15% -20%. This practice has become a major element of the high cost of plating.

Second half of 2008, LH plating invest 2 million first stop modernizing product line. Today, significant progress consumption efficiency, waste defect rate is reduced to below 5%. This one has 10% of the company frugal plating costs.

(003) shared fixed costs through economies of scope

Economies of scope are constantly made a major source of cost advantage. LH plating economies of scope from two sources.

First, through the development of alternative products and product lines modern approach greatly reduces both capital plating. Making power China plating on the market with a larger price competitiveness. Increased market share brings economies of scope.

Secondly, the development addition to Shenzhen, began development of Dongguan, Guangzhou, Huizhou and other foreign markets.

In the metal plating industry, because there is no local relationships, coupled with the impact of transport costs, general very few companies will go to develop foreign markets. But LH plating cost advantage to large customers rely for the main purpose of victory opened up foreign markets. Today, Dongguan, Guangzhou, Huizhou and other foreign market sales accounted for 40% of sales throughout the company. Victory develop foreign markets, further increasing the scope of economic advantage.

LH plating After these three strategies to reduce the cost of victory, deterioration in the macroeconomic environment under adverse conditions, still insist on a low-cost advantage.

04, Blue Ocean Strategy: metal plating companies differentiated road

As mentioned earlier, metal plating industry, market and product homogeneity serious homogeneity. LH plating how to break this homogeneity, I find blue ocean?

(A) Market Segmentation: Finding Blue Ocean

As mentioned above, the low-end market, brings together a large number of electroplating enterprises, coupled with the lack of product differentiation, making the low-end market competitive. As in recent years the market for a product's environmental performance and quality have become increasingly demanding, leading to further declines in low-end market, the market conditions deteriorate further, almost unprofitable. LH plating must expand into new markets.

According to product quality and environmental performance of products, metal plating industry, the market will be divided into nine segments. Intense competition in the market is 4,5,7,8 four. The five market segments which 1-3,6 fewer competitors, even higher margin, less competitive and more. Shown in Fig.

Figure 2: Market Segmentation metal plating

Comprehensive analysis of absorption of various market segments and the company's own resources and talents, LH resolution into 1-3,6 plating quality and environmental requirements of these five relatively high market segments.

(Two) product differentiation: Go Blue Ocean

Found the blue ocean, the next question is how to enter the blue ocean.

These market segments biggest feature is on product quality and environmental performance of requests is high. LH plating line modernization process through the product quality problem, and that a product's environmental performance has become the last one into the blue ocean barriers.

LH plating the U.S. "Consumer safety improvement Act" and the EU's RoHS compliance as a product specification. After nearly three months of effort, in September 2008 the victory of consumer products fit the European environmental laws.

Thus, LH plating victory into blue ocean. Despite the deteriorating market environment, but after the victory to implement a low cost strategy and Blue Ocean Strategy, 2008 LH plating still done the sales growth of 20%.

First, the whole of Guangdong market area metal plating industry is facing crises

(01) lead to the country's macroeconomic environment, rising costs.

2008 lot of variables in the macroeconomic environment. Much appreciated, deflation, and the introduction of the new labor law, and many other elements of the global economic crisis, making China's manufacturing industry in more than a decade experience flourished after experiencing the most severe challenge.

1, by the yuan's appreciation against the dollar impact of money constantly getting worse.

Electroplating enterprises in the high-end metal processing enterprises as key customers. Qi Cheng metal processing enterprises in export business mainly affected by exchange rate seriously. Money exchange rate changes on export prices influence. The money dollar exchange rate of 1:8.3 to 1:6.8 this year, the money for the dollar exchange rate rose by about 20%. The export business is far lower than the price rose 20%. Metal processing enterprises must be transferred to these pressures local electroplating enterprises body. Electroplating enterprises originally not make a big profit margins further tightening.

2, China People's Bank of deflation strategy adopted, the market is in the doldrums of the fuse.

Deflation brings more significant impact is progressive labor costs. With the price level rises, the overall level of resident life and death landing, to bring upward pressure on labor costs. The pressure of rising costs on to customers is difficult to complete the transfer.

3, the relevant state departments issued a new labor law, for the business sector had a negative impact.

The new labor contract law purposes, although safeguarding the interests of workers, but also brought the rise of labor costs. After the implementation of the new labor law, corporate salaries, benefits and related costs increased significantly.

4, the economic crisis

In early 2007, by the U.S. subprime mortgage crisis triggered by the global financial crisis, leading to a global recession. Electroplating industry is more seriously affected industries.

First, the global economic crisis has lead to consumer demand for landing. Second, the economic crisis countries will enhance the maintenance of domestic enterprises, and progress on the Chinese hardware products import barriers, thus affecting the metal plating business growth.

The four elements of metal plating companies directly incurred increased costs, which will certainly cause a lower cost developed countries to Vietnam and other Southeast Asian countries or regions metastasis. And this on the metal plating companies, the shrinking market will intensify competition within the industry.

(02) European and American consumer safety laws regulate access progress

In 2008, the United States issued a recall for Mattel co-handsome thing "Consumer Product Improvement Act of peace", the EU RoHS Directive subsequent progress on eight heavy metal testing specifications.

"Consumer safety improvement act" within the product is mainly aimed at children of lead and phthalates made to understand the request; EU RoHS specifications mainly for electrical and electronic equipment for lead, mercury, chromium and other heavy metals presents eight kinds understand the request.

The introduction of these compulsive decrees progress China export product testing specifications. This process for electroplating industry and raw materials put forward higher request, business operation costs significantly increased. Due to these norms to pay higher costs, making the loss of low-cost Chinese manufacturing competitive advantage. Metal plating industry was seriously affected, so always ignore environmental maintenance of metal plating industry fall into crisis.

(03) the increasingly fierce competition in the industry

The low-end market with the necessary plating low barriers to entry. 100,000 yuan will be able to engage in a small electroplating factory in Shenzhen, which makes the recent emergence of a large number of low-end metal plating factory. Coupled with the low-end market, market homogeneity, product homogeneity is very serious, leading to the fierce competition in the low-end market. Especially in recent years, clearly felt that the price getting lower and lower, increasing customer requests.

The high-end market because the scope of the required funding, technical strength, and high barriers to entry, business practitioners is much less than the low-end market. Related to the dispersion of the low-end market, high-end market concentration is high, competition is relatively mild and more. However, progress in Europe and consumer safety laws regulate access to high-end market has accelerated in the market homogeneity, product homogeneity aspects of trends, competition gradually intensified.

From the above analysis shows that market homogeneity and product homogeneity throughout the electroplating industry will intensify competition, whether it is in the low-end or high-end electroplating enterprises will gradually lose my competitive edge.

Second, the metal plating industry is facing critical issues

From the above analysis we can see, metal plating companies are now faced with two key problems: First, to digest in the macroeconomic environment and consumer safety laws in Europe and America under the influence of these two elements of the capital increase; Second, how in the increasingly fierce competition in the industry to survive and carried out. Rising costs and the homogenization of the whole electroplating industry will accelerate the deterioration of the industrial environment, whether it is at the low end or high-end electroplating enterprises will gradually lose my competitive edge.

That's before us is a problem in practice, electroplating enterprises to regain my competitive advantage.

Competitive advantage is a relative concept, the key is for the customer who can invent more than the value of its paid capital. About electroplating enterprises, this value is derived from the first low-cost, two is derived from the market and the product homogeneity break, looking for my blue ocean. Here is an example of Shenzhen LH plating, meticulous elucidated.

Third, the metal plating industry, low-cost strategy

From a global perspective, China is at the lowest level of metal processing industry, multi-industry enterprise engaged in low value-added metal processing, earned a meager processing fees. Practice under the present conditions of metal plating enterprises to reduce costs with very limited space.

In addition to reducing raw material procurement costs, improve labor efficiency, reduce inventory costs, layoffs and pay cuts, moving to lower-cost regions, such as conventional methods, it should also stop innovation in marketing, seeking ways to reduce costs.

(001) through technical innovation and development of less expensive alternative raw materials

First, think LH plating materials from alternative development to proceed reduce costs. Color products, for example nickel metal plating analyze the composition of capital. Shown in Fig.

Table I: nickel plating products constitute capital

Composition of nickel sulfate, nickel brightener other auxiliary board

The proportion of total capital 50% 30% 10% 10%

Table 1 shows the proportion of nickel plate to reach 50% of total cost, if the request is processed products of nickel-plated, then nickel plate is not being replaced. However, nickel sulfate, brightener and accessories is indeed able to replace.

One, LH plating nickel sulfate attempt to stop the main raw material substitution. Through experiments and found that magnesium sulfate Nickel sulfate has a good alternative, but does not affect the plating quality. This is an annual 75 percent for the company thrifty nickel sulfate capital.

Second, the development of nickel sulfate in victory replacement products, but also try to independent research brightener. Brightener price is high, accounting for 10% of total cost of plating, previously mainly by outsourcing. After nearly three months of development, LH electroplating brightener formulations developed. I began using brightener consumption. This backward integration parsimonious 50% per year for the company brightener capital.

Based on the above two nickel-colored unit cost reduction of 27.5%.

(002) Product Line modernization

Currently, the entire metal plating industry are using the traditional manual operation. Not only inefficient, but also by the operating personnel plating influenced the quality of instability. Scrap bad rate as high as 15% -20%. This practice has become a major element of the high cost of plating.

Second half of 2008, LH plating invest 2 million first stop modernizing product line. Today, significant progress consumption efficiency, waste defect rate is reduced to below 5%. This one has 10% of the company frugal plating costs.

(003) shared fixed costs through economies of scope

Economies of scope are constantly made a major source of cost advantage. LH plating economies of scope from two sources.

First, through the development of alternative products and product lines modern approach greatly reduces both capital plating. Making power China plating on the market with a larger price competitiveness. Increased market share brings economies of scope.

Secondly, the development addition to Shenzhen, began development of Dongguan, Guangzhou, Huizhou and other foreign markets.

In the metal plating industry, because there is no local relationships, coupled with the impact of transport costs, general very few companies will go to develop foreign markets. But LH plating cost advantage to large customers rely for the main purpose of victory opened up foreign markets. Today, Dongguan, Guangzhou, Huizhou and other foreign market sales accounted for 40% of sales throughout the company. Victory develop foreign markets, further increasing the scope of economic advantage.

LH plating After these three strategies to reduce the cost of victory, deterioration in the macroeconomic environment under adverse conditions, still insist on a low-cost advantage.

04, Blue Ocean Strategy: metal plating companies differentiated road

As mentioned earlier, metal plating industry, market and product homogeneity serious homogeneity. LH plating how to break this homogeneity, I find blue ocean?

(A) Market Segmentation: Finding Blue Ocean

As mentioned above, the low-end market, brings together a large number of electroplating enterprises, coupled with the lack of product differentiation, making the low-end market competitive. As in recent years the market for a product's environmental performance and quality have become increasingly demanding, leading to further declines in low-end market, the market conditions deteriorate further, almost unprofitable. LH plating must expand into new markets.

According to product quality and environmental performance of products, metal plating industry, the market will be divided into nine segments. Intense competition in the market is 4,5,7,8 four. The five market segments which 1-3,6 fewer competitors, even higher margin, less competitive and more. Shown in Fig.

Figure 2: Market Segmentation metal plating

Comprehensive analysis of absorption of various market segments and the company's own resources and talents, LH resolution into 1-3,6 plating quality and environmental requirements of these five relatively high market segments.

(Two) product differentiation: Go Blue Ocean

Found the blue ocean, the next question is how to enter the blue ocean.

These market segments biggest feature is on product quality and environmental performance of requests is high. LH plating line modernization process through the product quality problem, and that a product's environmental performance has become the last one into the blue ocean barriers.

LH plating the U.S. "Consumer safety improvement Act" and the EU's RoHS compliance as a product specification. After nearly three months of effort, in September 2008 the victory of consumer products fit the European environmental laws.

Thus, LH plating victory into blue ocean. Despite the deteriorating market environment, but after the victory to implement a low cost strategy and Blue Ocean Strategy, 2008 LH plating still done the sales growth of 20%.

関連するタグ:Metalplating,PlasticPlating

関連製品:

関連ニュース:

- Industrial robots used in metal plating industries trends

- Metal plating industry, occupational diseases: pneumoconiosis

- Eleventh China (Tianjin) International painting, electroplating and surface treatment Exhibition

- Teach you how to identify the merits of bathroom hardware electroplating products

- The company passed the ISO9001 international quality certification

- Function as the preferred plating accessories are popular Cabinet Hardware

- Plastic electroplating wastewater treatment technology

- Hardware electroplating and rail knowledge sharing

- Optimistic about industry trends plating bath hardware decoding upgrade Grand Slam

- Companies to join CPCA China Printed Circuit Association